The two-component liquid silicon potting technology is named so to be different from the single-component silicon potting technology.The material used is two-component liquid silicon.

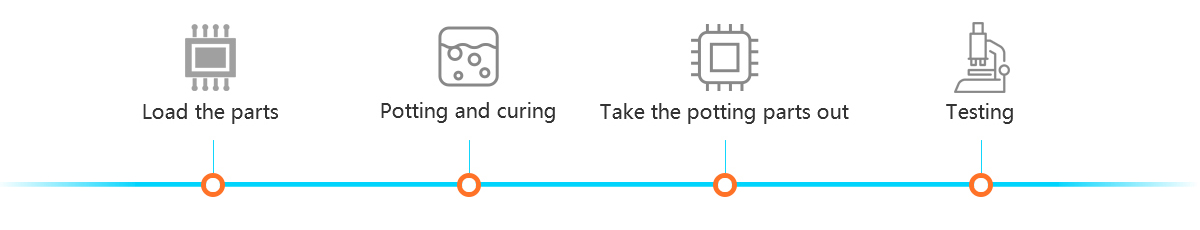

It is composed of two parts, A and B, of flowable liquid silicon. The B component contains platinum catalyst or other auxiliary, two components need to be mixed together in a certain proportion into the heated mold to solidify. It has low potting pressure (0-6mpa) and short curing time. The complete two-component liquid silicon potting technology is composed of two-component liquid silicon potting molding machine, mold set and corresponding potting parameters.

1. Coating and sealing of various electrical and electronic products and components.

2. Silicon pacifier, bottle, diving mirror, medical supplies and other finished products manufacturing.

3. All kinds of food grade mold materials and precision parts mold making.

4. Fiberglass, military, automobile and ship components mold manufacture.

5. High - grade simulation food, simulation cake mold and simulation sugar.

6. The easy design and rapid fabrication of high-precision prototyping.

7. Silicon dental, medical products, silicon wax figures, silicon dolls, silicon parts, silicon sealing ring, silicon rubber sheet and other silicon products and mold fabrication.

8. Precise casting equipment, carbon fiber composites, machine parts mapping.

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.